Test

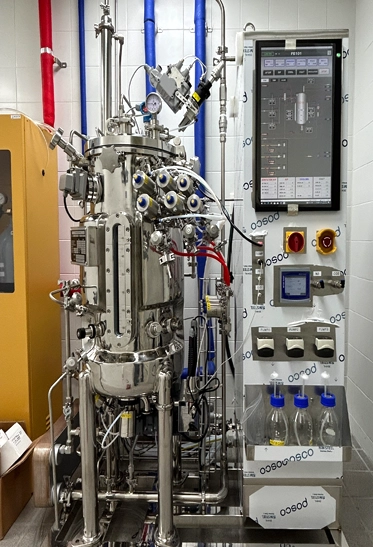

Fermentation

While working with bacteria and cultures can be complex, our fermenters are designed with these challenges in mind, resulting in a user-friendly system.

Microbial cultivation can be tricky, but our fermenters are built to handle even the most complex processes. We've engineered simplicity into every aspect, making them easy to use.

· Features

-

Customizable Solutions

We design and manufacture stainless steel fermenters for a wide range of microbes, from common bacteria to obligate anaerobes. Scale range from compact 10-liter units to large-scale 100,000-liter tanks.

-

Addressing Your Needs

Our fermenters consider crucial factors like oxygen supply, mixing, temperature control and maintaining anaerobic condition. We have the expertise and technology to tackle demanding situations, ensuring optimal conditions for even the most challenging microbes.

-

Versatility is Our Strength

Whether you need an anaerobic environment, high oxygen levels, or solutions for foaming, heat generation, or continuous production, we have the answer. BiosystemENG provides fermenters that meet the strictest safety standards and can handle high cell densities.

-

Integrated Systems

Our fermenters come equipped with built-in dosing systems for precise addition of acids, bases, and anti-foam agents.

-

Efficiency in Mind

We prioritize rapid heating and cooling to minimize negative impacts on your cultures and streamline your process.

- Lab Fermenter

- Pilot Fermenter

- Plant Fermenter

· Application

- Powerful industry control system with 15”LCD color touchscreen

- Working volume Vessel : 1~7 L

-

Vessel design

· Single shell · Double shell · Air lift type · Cell culture bioreactor - Multiple and Flexible Measurement and Control of pH, DO, Temperature, Foam/Level, Substrate addition, Gas Mixing, Agitation, Feed and Harvest Control, Constant Total Gas Flow Control, ORP and Turbidity

- Flexible choices Three tubing pumps and optional 2 x feeding pumps

- Superior gas mixing with up to 4 -Rotameters and Mass Flow Controller

- Choice of pre-configured systems

- Easy upgrade of multi-purpose use Supervisory Process SC ADA control software

-

Validation support available

· Option : 21CFR part11 compliance

· Application

- 10~800 L Working volume Vessel Fermenter

- Automatic Sterilization in Place (SIP) included and Automatic Cleaning in Place (CIP) available

- Multiple and Flexible Measurement and Control of pH, DO, Temperature, Foam/Level, Substrate addition, Agitation, Feed and Harvest Control, Optional Gas Mixing, Constant Total Gas Flow Control and ORP

- Flexible choices Three tubing pumps and optional 2-tubing pumps

- Superior gas mixing with Mass Flow Controller

- Easy upgrade of multi-purpose use Supervisory Process SCADA control software

- Extended documentation package available, inclusive Logbook and 3-Level password protection

-

Validation support available

· Option : 21CFR part11 compliance - Minimal Floor contact points for ease of cleaning

- Global spare part and service availability

· Application

- 1,000~50,000 L Working volume Vessel Fermenter

- Automatic Sterilization in Place (SIP) included and Automatic Cleaning in Place (CIP) available

- Multiple and Flexible Measurement and Control of pH, DO, Temperature, Foam/Level, Substrate addition, Agitation, Feed and Harvest Control, Optional Gas Mixing, Constant Total Gas Flow Control and ORP

- Addition tanks : Acid, Base, Antifoam and Feeding (SIP available)

- Superior gas mixing with Mass Flow Controller

- Easy upgrade of multi-purpose use Supervisory Process SCADA control software

- Extended documentation package available, inclusive Logbook and 3-Level password protection

-

Validation support available

· Option : 21CFR part11 compliance - Global spare part and service availability