Test

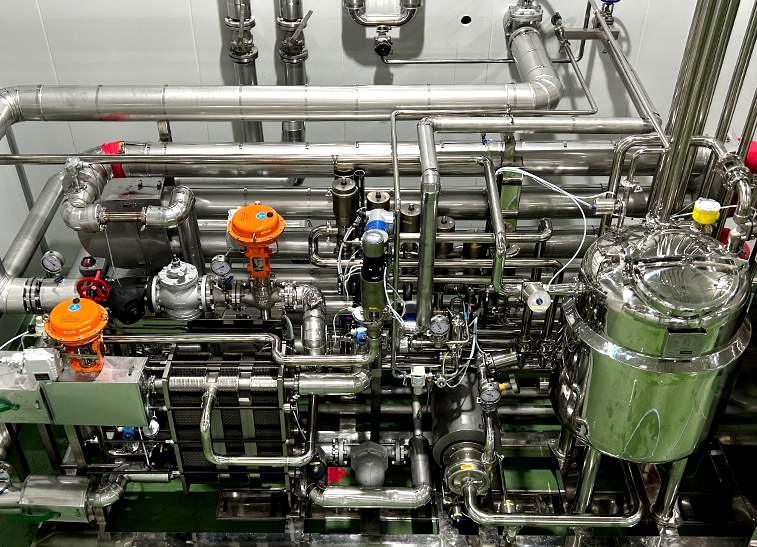

UHT/CIP

Ultra-high-temperature (UHT) continuous sterilization, also known as Ultra Heat Treatment (UHT) sterilization, is a process that heats milk to 135–154°C for 1–8 seconds, then rapidly cools it and packages it in sterile fermenters.

Mechanical elements (such as spray balls), chemicals (NaOH, acid), cleaning agent temperature, reaction and cleaning time all play an important role in the cleaning process. By optimizing each of the related components, BioSystemENG’s CIP system can be efficiently operated in the CIP process.

· Features

-

Cost saving

Fast and efficient sterilization process compared to tank sterilization: saves process time, energy and cost.

-

mass sterilization

Rapid and efficient mass sterilization

-

Independent sterilization

Independent sterilization

-

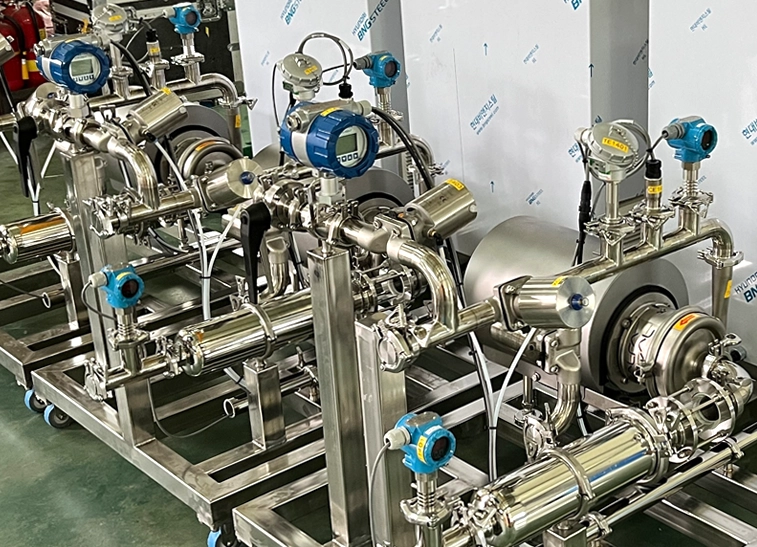

Designed to allow all units to be cleaned

Simply cleaning the vessel is not enough. Vessels, components, and piping connected to the transfer line are also important targets for the CIP process. At the production plant, the CIP loop is designed to allow all units to be cleaned and rinsed.

-

Cleanliness verification

PLC is a control system for cleaning to automate the CIP process. The control system can verify and document the cleaning process and cleanliness.

-

Safe cleaning

Safe and reproducible cleaning

- UHT

- CIP system

· Application

- The process kills all microorganisms and inactivates enzymes, which increases the productivity of fermentation.

- UHT processing can maintain nutrition condition in the broth under sterile temperature.

- Fast and efficient sterilization process compared to tank sterilization: saves process time, energy and cost.

- Rapid and efficient mass sterilization.

- Independent sterilization.

· Application

- Mechanical elements (such as spray balls), chemicals (NaOH, acid), cleaning agent temperature, reaction and cleaning time all play an important role in the cleaning process. By optimizing each of the related components, BioSystemENG’s CIP system can be efficiently operated in the CIP process.

- Simply cleaning the vessel is not enough. Vessels, components, and piping connected to the transfer line are also important targets for the CIP process. At the production plant, the CIP loop is designed to allow all units to be cleaned and rinsed.

- PLC is a control system for cleaning to automate the CIP process. The control system can verify and document the cleaning process and cleanliness.

- Safe and reproducible cleaning

- Recycle