Test

Automation

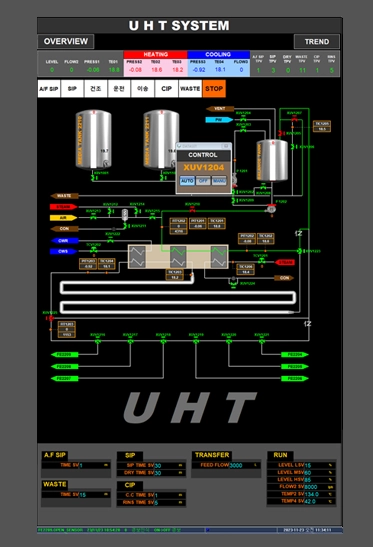

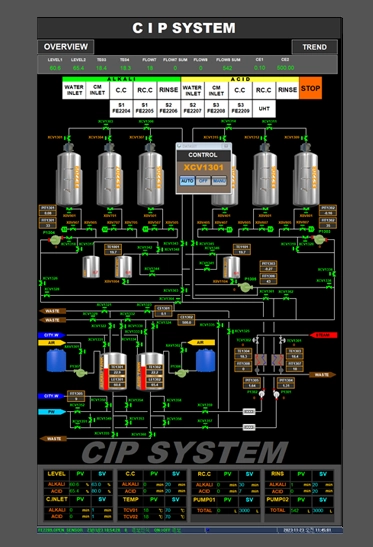

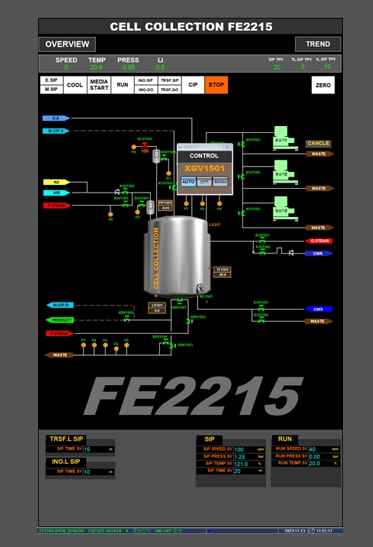

BioSystemENG control system is based on validated solutions. Customers can combine individual bioprocesses controlled by validated modules and take advantage of the many proven modules / functions / applications.

BioSystemENG control system greatly simplifies documentation and validation of biological processes and can be satisfied to your specific needs.

· Features

-

Years of experience

Based on our many years of experience, BioSystemENG provides customized control systems to our customers.

-

Automated 450 bioprocessing units

BioSystemENG Automation engineers have automated more than 150 systems over the years and have automated 450 bioprocessing units with more than 300 PLCs and 3,000 regulators.

-

Individual automation strategies

The automation architecture optimizes the implementation of individual automation strategies for the process, taking into account time / cost / quality.

-

Project execution in a short time

BiosystemENG automation enables project execution in a short time. We are able to provide a variety of support for specific control requirements and future upgrades due to improved bioprocessing during the entire service life of the plant / system.

-

Compliance with international standards

Biosystem ENG's automation engineers design automation according to customer specifications. Automation complies with international standards such as GAMP 5, CFR Part 11.

- Process control

- HMI

- SCADA

- Process Automation

· Application

- Experience is your best asset. Automated control of biological processes based on advanced process control and years of experience. Includes validated control systems, software and hardware solutions, open user interface.

- We treat many control units and sensors, example for control valves, pH, DO, temperature and pressure sensor, MFC and mass flow meter.

- We can apply and organize these control units and sensors to be reliable for our bioprocess.

· Application

- DP-DP Interface: The Profibus DP-DP interface enables real-time integration that is critical to the times and processes of third-party systems such as Centrifuge, CIP, WFI and Dispense Distribution in bioprocess.

- SQL interface: SQL interface is a validified interface for providing data to, or reading data from, Manufacturing Execution System (MES), Electronic Batch Record Systems (EBR), or ERP systems.

- OPC Interface: The OPC interface is a widely used standard in the plant automation and is supported by SCADA. It is used to integrate standardized third-party systems such as analyzers.

· Application

- We provide solutions for plant automation from field automation systems (sensors, actuators) to BioSCADA, DCS level, MES / ERP systems.

- All automation systems are designed based on PLC control module. PLC control modules can be combined according to system and process requirements.

- Laboratory and research bioprocessing units require monitoring and control of process variables and automation of sterilization. Control loops such as temperature, pH, pO2 and speed are regulated by local regulatory agencies and SCADA. Profile function can automate bioprocess step-by-step.

- In a production system, all of the various process units are combined and strategically controlled. This requires a higher level of automation by combining PLC and SCADA.

· Application

- We provide solutions for plant automation from field automation systems (sensors, actuators) to BioSCADA, DCS level, MES / ERP systems.

- BiosystemENG's automation team can provide various architectures and designs, as well as organize, program and validate (FAT / SAT) plant / system of biological processes. Automation is very closely related to the biological processes that we provide. A superior interface will maximize production efficiency.